Redefining Manufacturing Execution

The Challenge

Legacy MES systems are ill-equipped for the demands of modern JIT and discrete assembly environments, often hindered by:

- Rigid systems unable to adapt to dynamic production changes

- Limited real-time insights into production flow

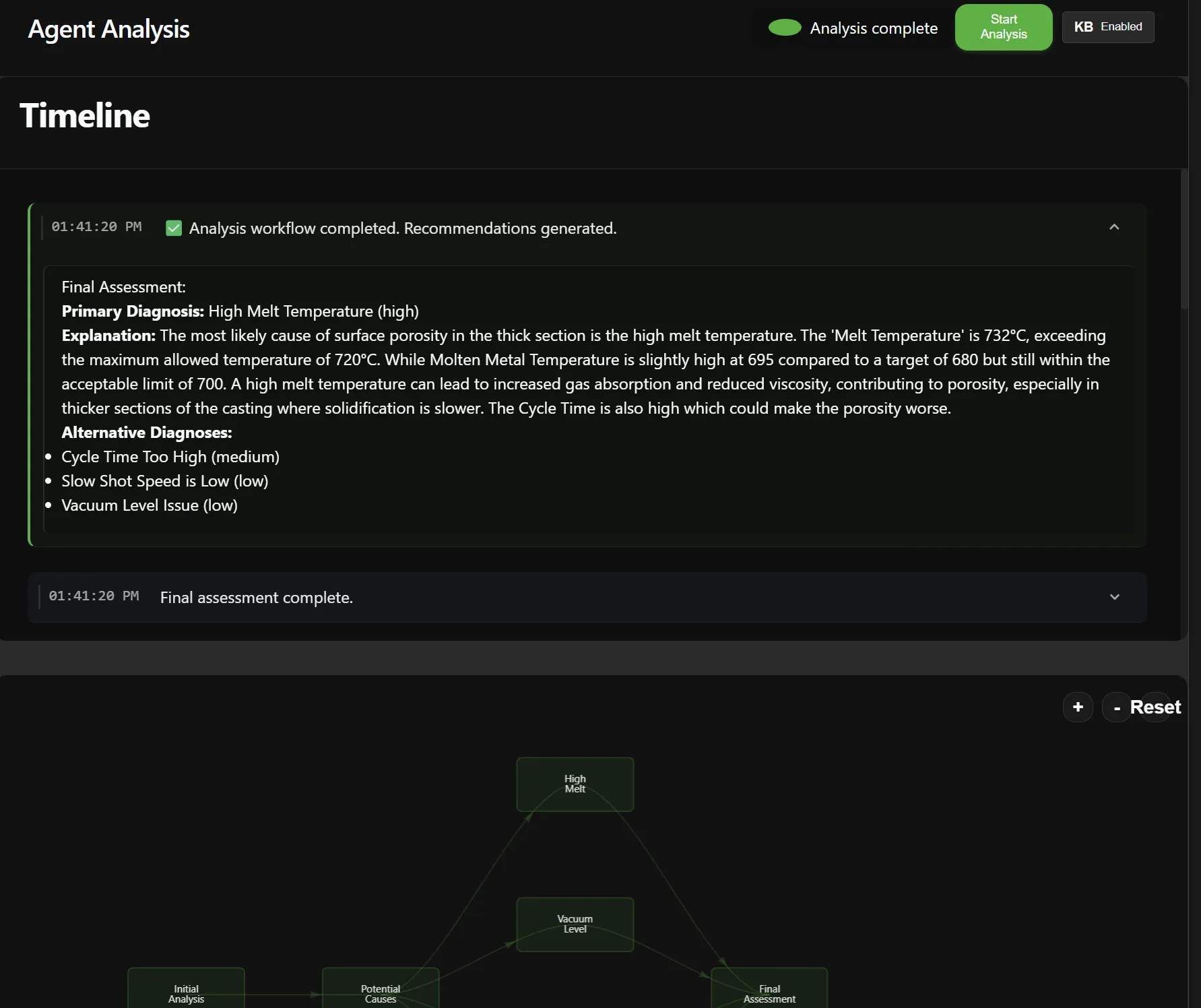

- Reactive approaches that fail to anticipate issues

- Complex, time-consuming setup processes

Our Solution

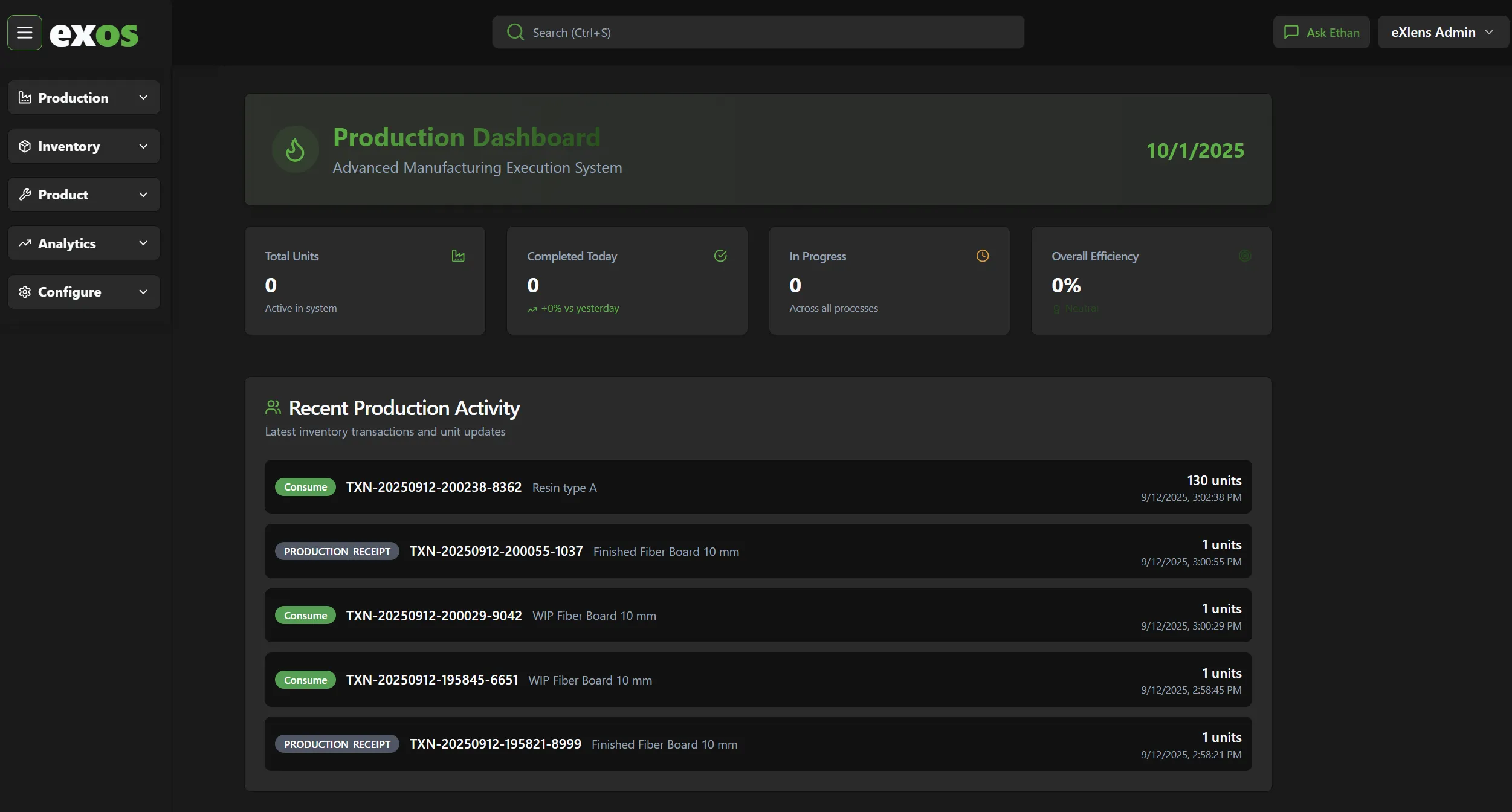

eXOS transforms manufacturing execution with an AI-first platform designed specifically for JIT and discrete assembly. By integrating domain-expert AI, it adapts in real-time to optimize operations, empower teams, and drive smarter decision-making, turning your factory into an intelligent, agile partner.

- AI-first platform designed for JIT and discrete assembly environments

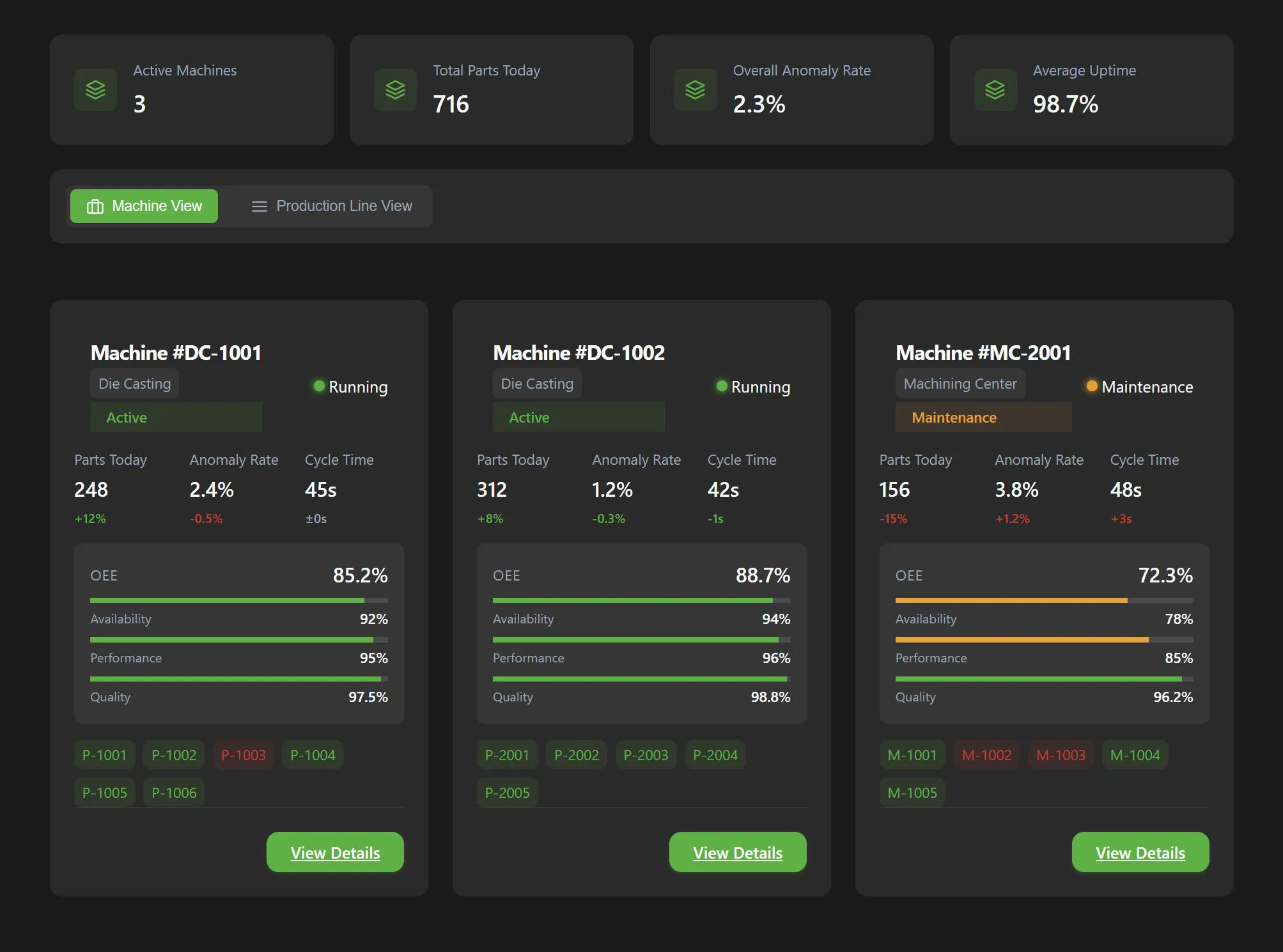

- Real-time adaptation to optimize operations and workflows

- Domain-expert AI integration for smarter decision-making

- Transformative platform that creates an intelligent, agile factory partner

eXOS is a revolutionary manufacturing execution system (MES) designed for discrete assembly and just-in-time (JIT) manufacturing. As a single, unified operating system to run the entire factory, it integrates advanced AI and domain-expert trained models to optimize production flow, prevent bottlenecks, and drive continuous improvement.